The Pentagon’s push for thousands of American-made drones to counter China‘s dominance has exposed a harsh truth: U.S. drone manufacturers are heavily reliant on Chinese components, creating a national security vulnerability (Note: not a Data Security issue…) that’s proving difficult to unravel. A recent Forbes article by David Jeans highlights the technical, economic, and regulatory hurdles U.S. firms face in building drones without Chinese parts, as escalating trade tensions and sanctions exacerbate the challenge.

A Supply Chain Stranglehold

China controls nearly 90% of the global commercial drone market and manufactures most critical drone components, including airframes, batteries, radios, cameras, and screens, according to Drone Industry Insights. This dominance stems from decades of investment, efficient supply chains, and government subsidies, leaving U.S. manufacturers years behind in developing comparable infrastructure.

“We are almost completely reliant on our major adversary for them, and our ability to make them,” said Josh Steinman, former supply chain security overseer at the National Security Council.

The reliance is so pervasive that even high-profile demonstrations reveal the issue. Last month, Vice President J.D. Vance was photographed wearing Chinese-made Skyzone drone display goggles at a U.S. Marines event in Quantico, Virginia. Major Hector Infante clarified the goggles were not military-issued and used only for viewing, but the incident underscores the challenge of avoiding Chinese parts entirely.

Sanctions and Supply Chain Disruptions

China’s willingness to weaponize its supply chain dominance adds urgency to the problem. In October 2024, Chinese sanctions targeted Skydio, the largest U.S. drone maker, cutting off its battery supply from Dongguan Poweramp Technology Ltd. Skydio, which has raised over $850 million, admitted it wouldn’t secure new suppliers until spring 2025 and began rationing batteries “This action makes clear that the Chinese government will use supply chains as a weapon to advance their interests over ours,” Skydio stated.

Pentagon Bureaucracy and Market Barriers

The Pentagon’s Defense Innovation Unit (DIU) oversees a “Blue List” of drones approved for military use, requiring them to be free of banned Chinese components like cameras and flight controllers under the National Defense Authorization Act (NDAA). However, the process is a bottleneck, approving only 23 of over 300 submissions in 2025. Companies like Darkhive and Brinc Drones faced rejections with little feedback, stifling growth.

“It’s easier to get sanctioned by the [People’s Republic of China] than it is to get on the Blue List,” said BRINC’s Andrew Cote.

The dominance of Chinese firm DJI, which commands 70% of the global market, further complicates matters.

“Until DJI is entirely banned, there’s not enough market to stand up a U.S. industrial base,” said Nathan Ecelbarger of the U.S. National Drone Association.

DJI’s lobbying efforts, including a lawsuit against the Defense Department, have so far blocked legislative bans, allowing it to continue supplying U.S. customers.

DroneXL’s Take

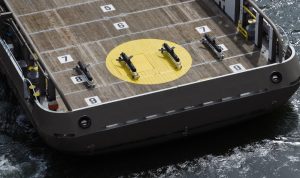

For DroneXL’s professional and recreational pilots, the reliance on Chinese parts poses both practical and strategic challenges. While U.S. manufacturers like Skydio and Neros are innovating, the cost and time required to build a China-free supply chain mean higher prices and potential delays for end users. The Pentagon’s Replicator initiative, aiming to deliver thousands of drones by August 2025, is a step forward, but its success hinges on overcoming bureaucratic hurdles and scaling domestic production. Pilots should brace for rising costs as tariffs and sanctions disrupt supply chains, while keeping an eye on emerging U.S. and allied suppliers. The path to self-sufficiency is long, but the stakes—national security and industry competitiveness—demand bold action.

Discover more from DroneXL.co

Subscribe to get the latest posts sent to your email.

+ There are no comments

Add yours